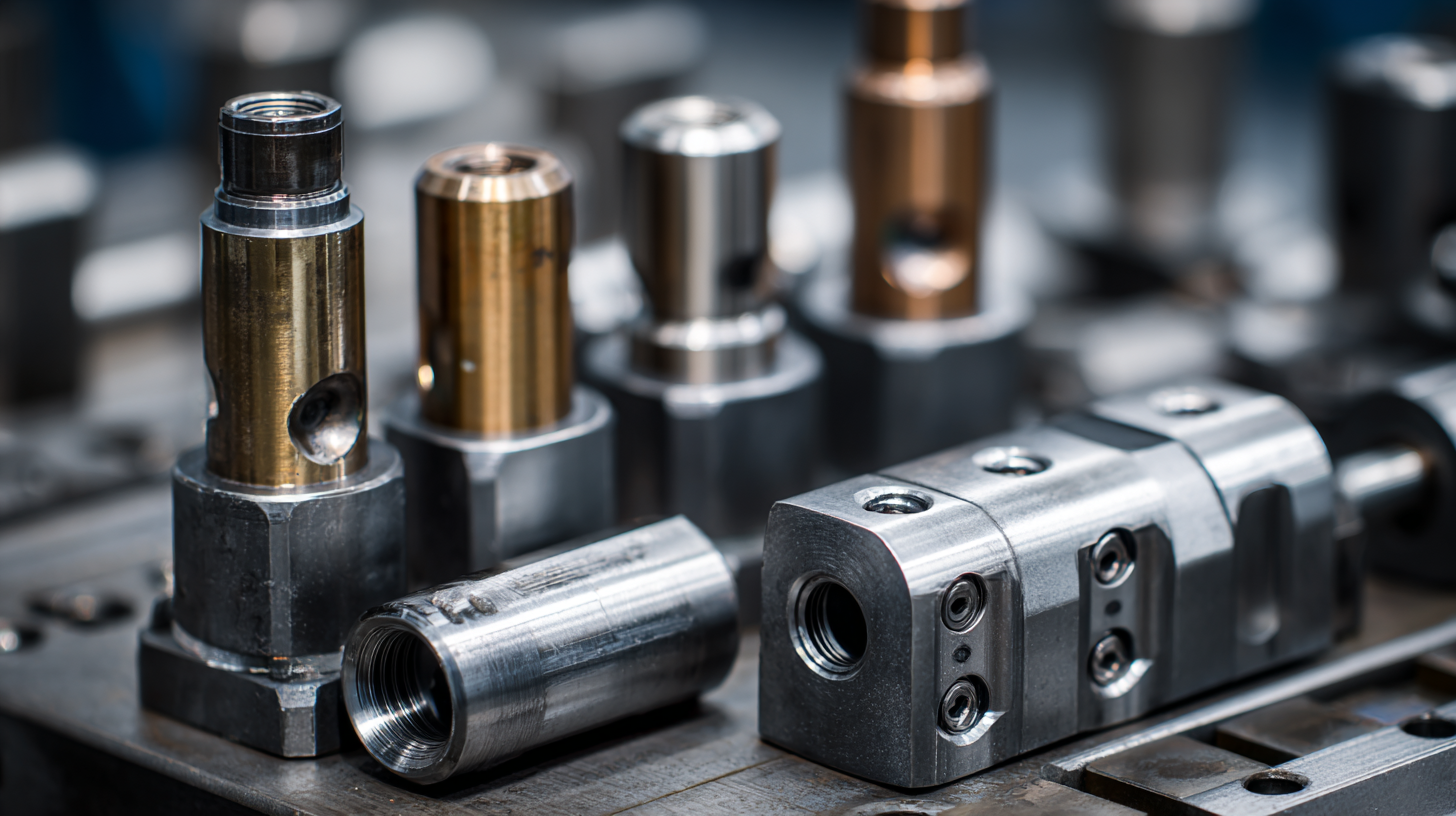

As industries continue to evolve, the demand for precision tools such as Roll Grooving Tools is on the rise. According to a recent market analysis by Global Industry Analysts, the global construction tools market is expected to reach $24 billion by 2025, driven by technological advancements and the increasing need for high-quality manufacturing equipment. This surge in demand emphasizes the necessity for businesses to find reliable suppliers that can provide top-tier Roll Grooving Tools to maintain competitive advantage and uphold stringent quality standards. With innovations in materials and design, selecting the right tools not only enhances productivity but also ensures safety and efficiency in operations. In this blog, we aim to guide you through the essentials of sourcing quality suppliers for Roll Grooving Tools, enabling you to make informed purchasing decisions in a rapidly changing market landscape.

When it comes to selecting quality roll grooving tool manufacturers, several key factors must be considered to ensure a successful partnership. First and foremost, the manufacturer's reputation and industry experience play a critical role. According to a report by Mordor Intelligence, the global market for roll grooving tools is projected to grow at a CAGR of 6.5% over the next five years. This growth highlights the importance of choosing suppliers who are established and have a proven track record of quality and reliability in manufacturing.

When it comes to selecting quality roll grooving tool manufacturers, several key factors must be considered to ensure a successful partnership. First and foremost, the manufacturer's reputation and industry experience play a critical role. According to a report by Mordor Intelligence, the global market for roll grooving tools is projected to grow at a CAGR of 6.5% over the next five years. This growth highlights the importance of choosing suppliers who are established and have a proven track record of quality and reliability in manufacturing.

Another essential factor is the production capabilities of the manufacturer. As indicated by a study from MarketsandMarkets, companies that invest in automation and advanced manufacturing processes often produce superior quality tools while reducing lead times. Therefore, it is beneficial to prioritize suppliers who utilize cutting-edge technology in their production lines. Furthermore, understanding the material quality used in the manufacturing process is crucial, as high-quality raw materials directly impact the durability and performance of roll grooving tools. Emphasizing these aspects can lead to finding a reliable supplier that meets your specific needs effectively.

When looking to find quality suppliers for roll grooving tools, leveraging industry standards and certifications is key to assessing supplier reliability. As businesses increasingly move towards global sourcing, understanding the various certifications that pertain to your industry can vastly improve your supplier selection process. Certifications like ISO 9001 ensure that suppliers maintain high-quality management systems, while relevant safety certifications provide assurance that products meet industry standards and regulations.

Moreover, evaluating a supplier's capabilities goes beyond simply reviewing their certifications. It's essential to look into their past performance, customer feedback, and ability to meet specific demands such as lead times and production capacity. In 2024, as companies prioritize efficiency and innovation, utilizing tools that analyze supplier data can help make informed decisions. By integrating these practices into your sourcing strategy, you can foster a reliable supply chain that enhances your business's overall performance.

When it comes to procuring roll grooving tools, the decision-making process often boils down to a critical evaluation of cost versus quality. It’s tempting to opt for the cheapest option available, especially when budgets are tight. However, sacrificing quality can lead to subpar results, increased downtime, and the necessity for more frequent replacements. Investing in higher-quality tools typically translates to enhanced performance, durability, and ultimately, cost savings over time. The key is to balance these factors effectively, ensuring that the tools you choose meet both your functional and financial needs.

To make informed decisions, buyers should conduct thorough research on potential suppliers, taking into account not only the price but also product reviews, warranty offerings, and the supplier's reputation in the industry. Engaging with knowledgeable vendors can provide insight into the intricacies of tool performance and longevity. By focusing on a comprehensive evaluation framework that prioritizes quality, buyers can secure reliable tools that will perform consistently, contribute to higher productivity, and yield better overall returns on investment. This strategic approach will pave the way for a more successful and sustainable procurement process in the long run.

When looking for quality suppliers for roll grooving tools, exploring supplier reviews can be incredibly beneficial. Customer feedback provides a glimpse into the reliability and efficiency of a supplier’s products. Reading both positive and negative reviews helps create a comprehensive picture of what to expect. Look for suppliers with a strong presence in the industry and those who have satisfied customers, as this can indicate consistency in quality and service.

Case studies also serve as valuable resources for supplier selection. They offer real-world examples of how suppliers have met the needs of their clients, showcasing their capabilities and problem-solving approaches. For instance, a case study featuring a supplier who successfully delivered customized solutions for a demanding project can illustrate their adaptability and innovation. When you find such case studies, take note of key metrics such as delivery times, customer satisfaction rates, and the specific challenges addressed.

**Tips:** Always cross-reference multiple reviews before making a decision, as this can help balance out any anomalies. Additionally, reach out to previous clients if possible; their insights can provide a clearer picture of what working with a supplier entails. Consider suppliers that participate actively in industry forums, as this often reflects their commitment to quality and customer engagement.

When establishing a sustainable supply chain, creating long-term partnerships with suppliers is essential for the success of your business. Building these relationships involves trust, transparency, and a shared vision for the future. By fostering open communication, companies can better align their goals and anticipate each other's needs, resulting in a mutually beneficial partnership.

**Tips: Assess their sustainability practices** - Before choosing a supplier, evaluate their commitment to sustainable practices. This includes their policies on waste reduction, resource utilization, and ethical labor practices. Partnering with suppliers who prioritize sustainability will not only enhance your brand's image but also contribute to a healthier planet.

**Tips: Invest in technology for better collaboration** - Utilizing technology for collaboration can streamline processes and improve the efficiency of communication between you and your suppliers. Tools such as shared project management platforms or real-time inventory tracking systems can foster better coordination, helping both parties adapt to changing demands quickly.

**Tips: Foster continuous improvement** - Encouraging suppliers to engage in continuous improvement initiatives can strengthen your partnership. By working together on innovations and efficiency upgrades, both businesses can benefit from reduced costs and enhanced product offerings, ensuring a thriving and sustainable supply chain.